M7140 Horizontal Axis And Rectangular Table Surface Grinder

2022-11-09

2022-11-09

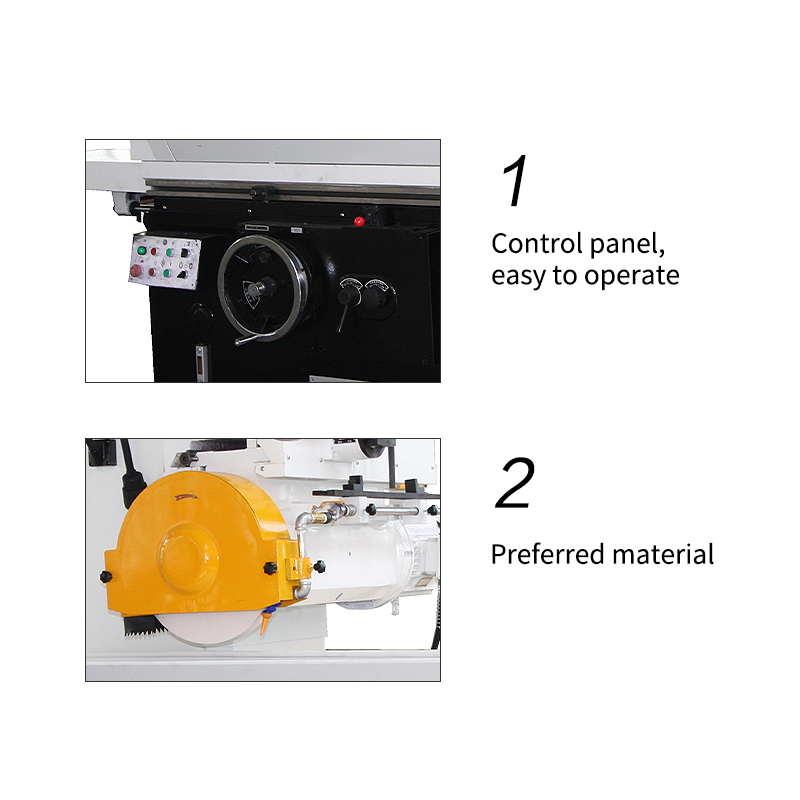

This grinder is used for grinding around the wheel. It can grind various work-piece surfaces made of steel, cast iron and non-ferrous metals. It is applicable to various machining workshops and machine repair workshops. The machine tool has the following characteristics: 1. The longitudinal motion of the worktable and the cross feed of the grinding head are hydraulically driven, and the cross feed can also be manually operated. 2. The grinding wheel shaft is driven by a built-in motor. 3. There is a device to control the thermal deformation, so the thermal deformation is small. 4. The vertical feed belt can be lifted quickly or manually.

Processing features of M7140 surface grinder:

1. The surface grinder grinds the surface of the work-piece with the periphery or side of the grinding wheel. The work-piece can be fixed on the workbench or fixed on the electromagnetic chuck, and its material can be steel, cast iron or non-ferrous metal.

2. The whole machine is featured by stable movement, good accuracy, reliable performance and low noise, which is especially suitable for grinding the mechanical metal workpiece surface.

3. The longitudinal motion of the worktable and the transverse motion of the grinding head are both driven by hydraulic pressure, with stepless speed regulation. The transverse movement of the grinding head can also be manually operated.

4. In addition to manual feeding, the vertical direction of the grinding head is also equipped with a motorized fast lifting mechanism, which can reduce labor intensity and improve work efficiency.

Sichuan Chuanmominji CNC Machine Co., Ltd. was established on October 26, 2011. Chuanmominji is a leading enterprise in the grinding machine industry in China, which focuses on research and development, production and sales of various machine tools, applies advanced design concepts, closely follows the forefront of scientific and technological progress, and creates a pioneer in the industry. Chuanmominji not only has the advanced imported processing equipment from West Germany, Wadrisi, the Czech Republic, Germany, Italy, the United States, Russia and other countries, but also has nearly 100 professional and technical talents and skilled craftsmen. The company mainly researches and develops grinding machine series: CNC gantry type surface grinder series, horizontal axis rectangular table type surface grinder series, CNC movable column type surface grinder series and CNC gantry guide rail grinder, CNC horizontal axis rectangular table type surface grinder, horizontal axis circular table type surface grinder, tool grinder, internal and external cylindrical grinder, vertical circular table grinder, centerless grinder, gear grinder, special grinder and more than 50 varieties. For many years, CMR has been drawing on foreign advanced technology and relying on independent innovation to continuously narrow the gap with foreign advanced technology. By developing the error modeling principle and analysis model of the longitudinal motion of the grinding machine workbench and the vertical feed motion of the grinding head, the precision control model and error compensation method of the grinding machine are proposed, and finally the integration of 3D CAD modeling, FEA for finite element structure analysis, optimization design, driving elements, control system design, accuracy evaluation and error modeling of high-precision grinding machine series products is realized, A series of high-precision grinding machines meeting the requirements of machining performance have been developed and popularized. Through joint development with Chinese Academy of Sciences, Sichuan University, Southwest Jiaotong University, Xihua University and other professional institutions, the company overcame problems and further developed new products. The MK7140C high-precision CNC surface grinder developed and launched is the first product in the province. The CNC gantry grinder developed by Chuanmominji is aimed at the national strategy of "German Industry 4.0" and "Made in China 2025". It is required for high-end CNC grinding machines in China at present, fills the gap of CNC grinding machines with independent intellectual property rights in China, and is a grinder that many domestic enterprises must choose. It is applied to large-scale high-precision molds, aerospace, shipbuilding, national defense and military industry, large-scale precision mold manufacturing, military equipment, high-speed rail parts Auto parts, motorcycle parts, plastic machinery, textile machinery, printing machinery, packaging machinery, power machinery and other industries. The development and application of CM-K series gantry CNC surface grinding machine can improve the independent research and development capability of large and high-precision grinding machines in China, meet the development requirements of machine tool product research and development technology, and meet the development needs of the overall situation of the precision machine tool industry.

Contact Person:Yang Zuolun

Email:1215973999@qq.com